| Category : | HMI |

| Project : | BRS HMI TCM |

| Description : | HMI developement |

| Year : | 2015 - 2016 |

| Customer : | Big River Steel Inc. - USA |

| Platform : | WinCC |

BRS HMI TCM

Project Target

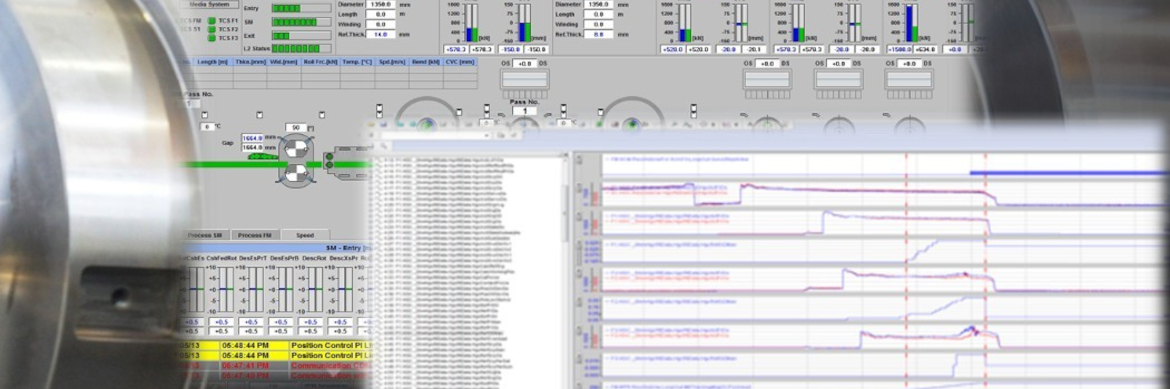

Design the layout and program parts of HMI (Human Machine Interface) according to the customer's order.

Project made for SMS Group GmbH GERMANY

Technical data

- Platform : WinCC (Win, Win Server)

- Technology : Tandem Continuous Cold Mill

- Hardware : Server, Redundancy server, HMI clients

- Communications : TCP/IP, ODBC, RFM, SQL

Overview screens:

Screens that are collecting all important information for operators or maintainance staff at one place.

Hydraulic screens:

Screens of hydraulic system supporting oil for hydraulical movements.

Stands control screens:

Screens showing status of all controllers of movements in each rolling stand.

Roll change screens:

Screens showing roll change sequence step by step, conditions to execute next step, data of incoming roll set, status of movements, status of roll change drives...

Material and coil tracking screens:

Screens showinng positions of coils waiting for rolling or already rolled and positions of material head and end.

Cooling screens:

Screens with status of cooling valves and information about cooling amount for each part of rolling mill.

Emulsion control screens:

Screens of emulsion system preparing cooling emulsion for all parts of rolling mill.

Entry section screens:

Screens showing the status of entry sections for transporting material from pickling line.

Exit section screens:

Screens showing the status of exit sections for transporting the coils from the rolling process.

Drives screens:

Overview of all drives of rolling mill, switching them ON or OFF.

Diagnostic screens:

Screens for diagnosis to see the status of each part of system.

Error screens:

Screens with errors and warnings overview and posibility to filter them for better investigation of problem.

Master systems data exchange screens:

Screens handling data exchange from and to superior systems.

Integration Test:

Integration test was done in Germany at SMS Group GmbH company. The main point of integration test is to simulate whole technological entity and test all programmed parts together to reduce the commissioning time at customer.

Commissioning:

The commissioning was done at the end custommer in the USA. The main supplier of whole technology and master of whole commissioning was SMS Group GmbH company. The commissioning included communication tests, signals exchange test, Users levels set-up, custommer training...